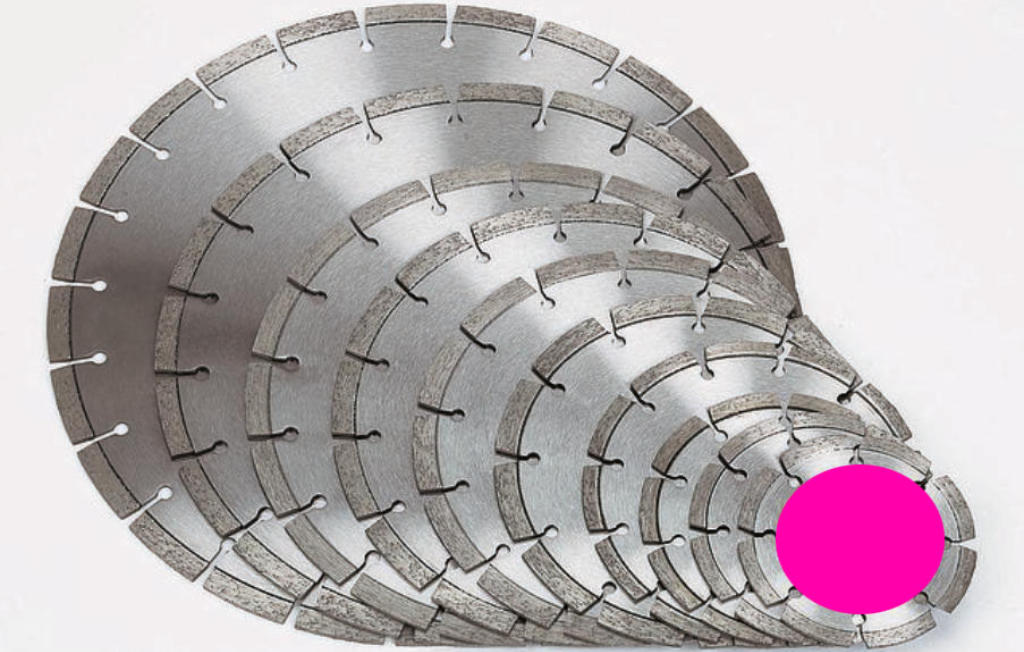

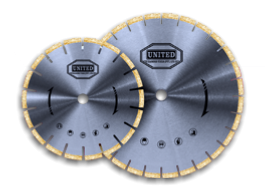

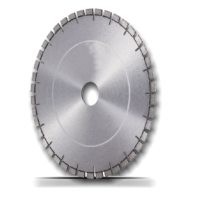

Marble Diamond Blades are engineered to provide a smooth and

fast cutting performance on granite, marble, and hard

stone. They have deep segments that are designed

for abrasion resistance and protecting the diamond

blade from undercutting.

The blade does not only have diamonds on the

segments, but also has engineering technique,

which ensures most smooth and fastest cutting. It

has 60mm - 80m arbor. It is designed to cut

materials such as softer marbles, travertines,

soapstones, and alabaster without the chipping and

cracking commonly associated with the cutting

process. Wet cutting is recommended.

There are no products matching the selection.

Diamond Blades for Marble & Granite Cutting

Specifications

Code #

Segment Size

Arbor Size

Meterial to cut

Diameter

Special Note

UE-3116

40x4.6x10 mm

60 mm

Marble

18” Spl (Inch)

Wet cutting only

UE-2219

40x3.8x10 mm

60 mm

Marble

16” (Inch)

Wet cutting only

UE-3822

40x4.8x10 mm

60 mm

Marble

18” (Inch)

Wet cutting only

UE-3117

40x4.8x10 mm

60 mm

Marble

18” (Inch)

Wet cutting only

U-5563HH

64” (Inch)

24x20/19x7.2

100 mm

Granite

Wet cutting only

U-5563HH

48” (Inch)

24x20/19x7.2

100 mm

Granite

Wet cutting only

U-5563HH

32” (Inch)

24x20/19x7.2

100 mm

Granite

Wet cutting only

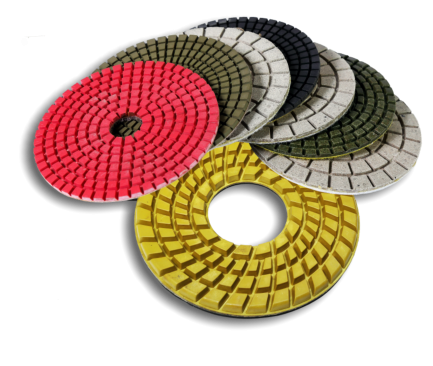

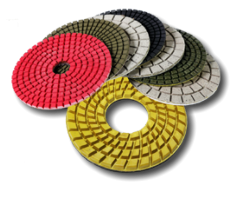

Granite, Marble, and Natural Stone Pads are

designed to polish and

grind counter tops, floors, slabs, and walls. We

offer pads

that are made with high quality diamonds and

resins

to grind and polish the most demanding marble

and

granite surfaces. Our resin pads perform all the

tasks while leaving an amazing polish on the

stone. The lower grit polishing pads or diamond

grit sanding pads such as the 50, 100, 200 grits

are more aggressive. The lower grit diamonds

pads are used to lightly grind down the granite

or stone. Each grit-polishing pad of the set is

progressively less aggressive than the pad

before. Each grit progression removes the

scratches left from the diamond pad used prior.

The

400-

grit diamond pad is considered more of a hone

finish than a

grind or polish. The 800, 1,500, and 3,000 grit

polishing pads are the final steps in the

polishing process and used to get the wet or

shiny look. A typical slab of granite or

marble goes through the

entire polishing

process, starting with

the lower grit

polishing for creating

some light scratching

or grinding and

continuing through the

higher grits for desired look.

Depending on the job some

steps may be cut out in the

beginning or end of process.

Granite and Marble Floor Polishing Pads

Home

Segmented Diamond Saw

Blades for Marble

Segmented Diamond Saw

Blades for Granite

Large Diameter Saw Blades

for Block Cutting

Round Polishing Pads for

floor and Slab Polishing

Cassani Polishing Pads for

floor and Slab Polishing

Fast Cutting and Long Life

Customized Diamond Segments

“A” Shape Cassani Cutting

Disks for floor Polishing

Teeth Shape Cassani Cutting

Disks for Very fast floor cutting

5 Extra Yellow Disks for fine

finish, Glossy and wet look

Electro-plated core bit drill

for ceramic and tiles, web

and dry available

Segmented Core Bit Drill for

Concrete, Bricks wall and

Road Drilling

Segmented Grinding Cup

for Surface finishing and

Slab calibration

All rights reserved by United Diamond Tools Pvt. Ltd. 2019 - 2020

Designed by SM Brothers 0345-555 96 83

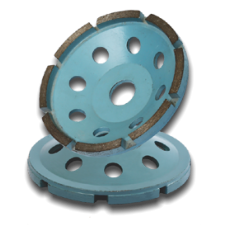

Granite diamond segment is one of the most advantaged Products in our

company. Our granite diamond segments come with evenly distributed

diamond particles within the much customized bond/formula. Its cutting

efficiency is very good as compared with

counterparts, and

the lifespan of diamond segment is 1.2 times

longer than other traditional cutting segments.

To meet customers' different demand on the

diamond segments, we can improve the

formula/bond according to the problems during

cutting. For example, increasing the sharpness and

stability or extending cutting life.

Our diamond segments are ideal for cutting various

granites with different hardness, such as Green

Granite, Black Granite, Red Granite and Grey

Granite.

Our granite diamond segments are widely

acknowledged in Pakistan market and being sold across

the country. You can save your cost and you will get more than your

expect!

The advantage of our Diamond Segment

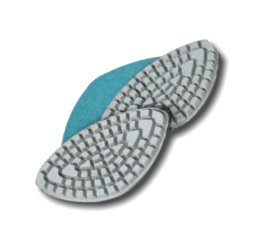

United Diamond Cassani Disk

The Diamond Cassani segment is part of our range for the

grinding and polishing of marble and granite floor pavements

with Heavy and light floor grinding machine. They are used in

sets of 3 units. The Diamond Cassani is equipped with high

abrasive diamond metal segments for grinding marble and

granite floors, offering the maximum abrasive capacity

on all types of materials. Diamond Cassani have high

strength, excellent wear resistance, low friction

coefficient, high grinding efficiency and low grinding

force generates hence produced less heat in the grinding

process. Diamond Cassani is the best solution for large

areas of thin coating removal, leveling and smoothing

high spots in marble and granite floors. Their segments

are designed for aggressive grinding of marble and

granite to make short work of your larger projects.

Diamond Cassani is also ideal for the initial steps in marble

and granite slab polishing procedures. we have also polishing

numbers available in our stock for final finishing and shiny polishing.